Need Precision Metal Cutting? What a CNC Laser Cutter Can Do for Your Project

Common materials include mild steel, stainless steel, aluminum, brass, and copper, in thicknesses that vary by machine power and focus optics. The result: accurate parts that often require little or no secondary machining.

The Process: How a Job Moves from Idea to Finished part

- Design & quoting: You supply a drawing, CAD file, or even a hand sketch. JLL Fab reviews geometry, nesting options, and material choices to create an efficient quote.

- Programming: Engineers convert the CAD data into a CAM program that sets cutting order, power, speed, assist gas, and pierce parameters. Correct setup avoids edge discoloration and heat distortion.

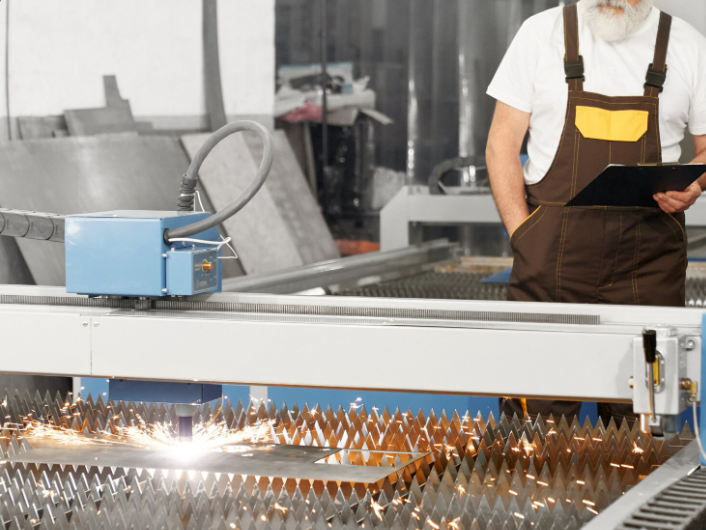

- Cutting: The CNC laser executes the program. High-power lasers cut thicker plates. Lower power and fine optics produce crisp edges in sheet metal. Automated part removal and nesting reduce material waste.

- Finishing & inspection: Depending on tolerance and surface needs, parts may be deburred, bead-blasted, or inspected with measurement tools before delivery.

This controlled workflow keeps the process repeatable and predictable.

Benefits of CNC laser cutting for metal projects

- Precision and repeatability: Tight tolerances and consistent parts across runs.

- Minimal secondary work: Clean edges reduce or eliminate grinding and chamfering.

- Fast turnaround: Quick setup and rapid cutting speed shorten lead times.

- Material efficiency: Nesting software maximizes sheet yield and lowers scrap.

- Complex geometry: Intricate shapes, small holes, and fine details are possible without special tooling.

- Scalability: Works for one-off prototypes and high-volume production alike.

These advantages translate into lower total cost of ownership for many projects.

Why Choose JLL Fab for Your Laser Cutting Needs?

JLL Fab blends modern CNC laser equipment with experienced process engineers. That means you get more than a machine operator. You get material guidance, optimized nesting, and quality checks that prevent rejects.

JLL Fab also supports quick-turn prototyping, short production runs, and volume manufacturing with consistent scheduling. Local service and communication shorten revision cycles, so design tweaks and iterative testing happen faster than with distant vendors.

Frequently Asked Questions (FAQs)

Q: What thicknesses can a CNC laser cut?

A: It depends on the laser power and the metal. High-power fiber lasers can cut several inches of mild steel; thinner sheet metals are cut with finer optics for cleaner edges. JLL Fab will recommend the best setup for your material and tolerances.

Q: How tight are laser-cut tolerances?

A: Typical tolerances are in the range of ±0.010″ (±0.25 mm) depending on geometry and material. For critical fits, JLL Fab reviews drawing callouts and proposes achievable tolerances during quoting.

Q: Do laser-cut parts need extra finishing?

A: Many parts are ready as-cut. When required, JLL Fab offers deburring, edge blending, and surface treatments like powder coating or plating.

Q: Can you handle custom or one-off prototypes?

A: Yes. Laser cutting is ideal for prototyping because it removes the need for hard tooling and lets you iterate quickly.

Q: How should I prepare files for quoting?

A: Provide a DXF or DWG file with scale and material notes. If you don’t have CAD, a clear sketch or PDF with dimensions works JLL Fab can help convert it.

Conclusion

A CNC laser cutter for metal delivers fast, accurate cutting for parts ranging from delicate prototypes to rugged production pieces. The real value comes when a fabricator pairs modern equipment with engineering know-how to optimize nesting, cut strategies, and finish processes.

If you want parts with tight tolerances, clean edges, and predictable lead times, JLL Fab can help you turn designs into production quickly and cost-effectively. Contact JLL Fab today to discuss your next metal cutting project.