Equipment Rigging in Houston, TX

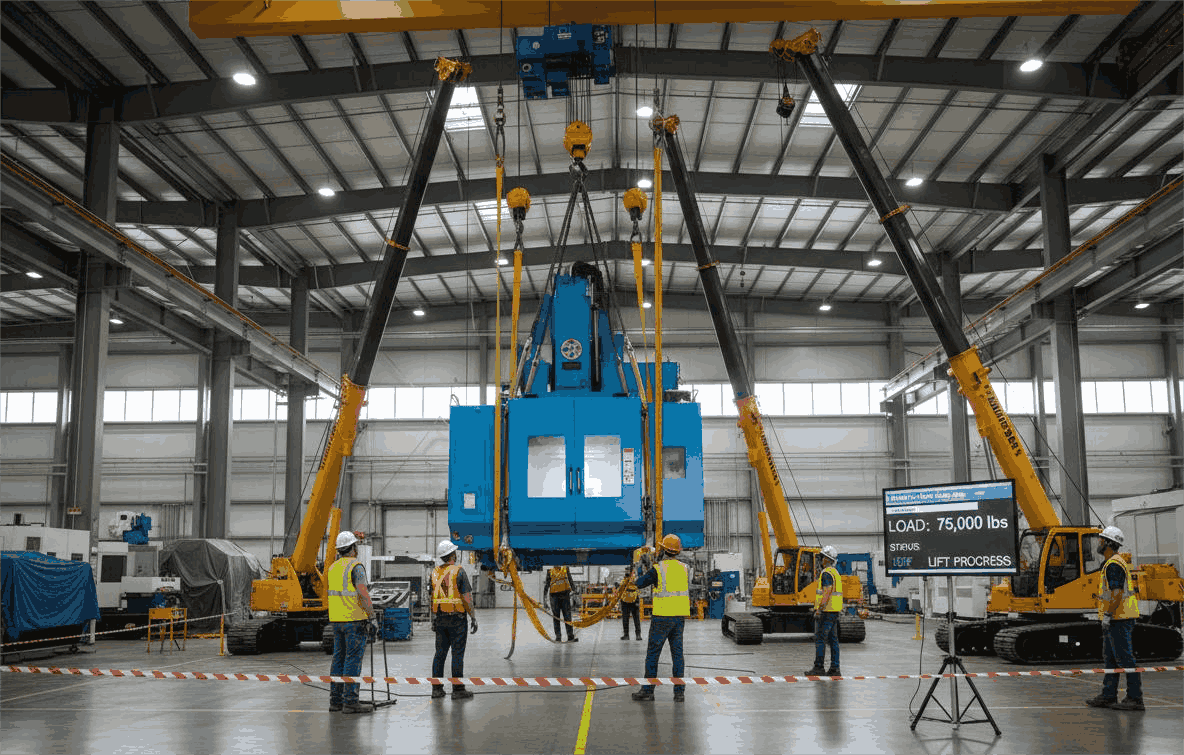

Heavy equipment moves demand planning, precision, and safe execution. At JLL Fab, the team provides experienced equipment rigging to minimize downtime and protect people, machinery, and facilities.

We begin every project with a site review, lift plan, and hazard analysis to define pick points, clearances, and staging. Our process also includes coordinating logistics such as equipment transport routes, lift sequencing, and crew assignments. This ensures every move is performed efficiently and meets all safety and compliance standards.

Projects are coordinated to fit production schedules and facility access windows, ensuring lifts occur on time and with minimal operational disruption. JLL Fab is based in Tomball, TX, and serves in Houston, TX, and nearby areas.

Complete Equipment Rigging Services in Houston, TX

Every rigging project is unique, and our service offerings are built to match that variety. Below is a structured look at the specialized equipment rigging Services we provide.

Design & Lift Planning

We start with detailed lift plans and engineered diagrams that define pick points, clearances, and sequence. This phase establishes predictability and safety, forming the foundation of all equipment rigging services handled by our team.

Lift Planning & Engineering

We manage crane selection, setup, and control using certified lifting and rigging equipment. Each plan includes load calculations, center-of-gravity reviews, and structure analysis to ensure a safe lift under real operating conditions.

Heavy Equipment Lifting & Relocation

From machinery moves to plant repositioning, we execute controlled single and multi-point lifts. Each relocation is coordinated to maintain structural balance, prevent shock loading, and minimize downtime across production facilities.

Rigging Equipment & Safety Compliance

We provide and maintain slings, shackles, and spreader bars to current standards. Every lift follows inspection protocols, certification records, and toolbox briefings to uphold safety compliance and operational consistency.

Load Securing & Transportation

Our team handles crating, skid fabrication, and tie-down procedures to secure heavy assets during transport. Attention to balance, restraint, and vibration control keeps critical components intact through transit and delivery.

Precise Positioning & Installation

Once on-site, our certified riggers perform fine alignment, grout placement, and pad setting. Using precision instruments, each piece of equipment is leveled, anchored, and verified before system start-up or commissioning.

Benefits of Choosing Equipment Rigging

Every well-planned lift pays off in safety, time, and cost. Choosing expert rigging means you’re choosing control and confidence.

- Safety First: Rigging against engineered plans leads to a considerable decrease in the risk of personnel, equipment, or infrastructure.

- Reduced Downtime: Comprehensive scheduling and accurate implementation minimize the interruptions in the production and accelerate the swiftness of the service restoration.

- Asset Protection: The costly equipment can be safeguarded by proper rigging techniques and rated hardware to prevent stress and breakages.

- Controllable Expenses: A well-planned project will give fewer contingencies and unforeseen setbacks, which enhance cost predictability.

- Single-Point Responsibility: End-to-end responsibility is achieved by having a single managed team involved in planning, lifting, transport, and placing.

Such advantages are achieved by managing to use certified equipment and an appropriate mix of equipment and staff in a disciplined way.

Why Choose JLL Fab for Equipment Rigging?

Selecting the right team determines the success of every lift. Here’s why JLL Fab stands out as a trusted partner for equipment rigging Services.

- Skilled Workforce: Field crews and leads have years of experience in heavy lift and are trained to interpret complicated lift environments and hazards.

- Full-Service Coordination: Fewer handoffs and better communication mean that in-house planning, equipment sourcing, and installation coordination.

- Reliable Supervision: A professional rigger at the senior level is in charge of planning and executing all critical lifts to ensure that the lift plan is adhered to.

- Contemporary Equipment and Inspections: We are able to maintain and inspect cranes, hoists, and rigging equipment to the industry standards in order to ensure every lift utilizes tested and reliable equipment.

- Local Responsiveness: JLL Fab is based in Tomball and operates in the facilities of the Houston area, where it offers facility-timely site visits and local lift support to fit within tight windows.

When a project requires a dependable professional rigger to oversee load control and final placement, clients choose our team for consistent outcomes.

Get Started with Expert Equipment Rigging Today

Planned, executed, and documented lifts protect your people and your plant. For reliable, safe, and efficient equipment rigging, we deliver technical planning, certified crews, and the right equipment for the job. JLL Fab is based in Tomball, TX, and serves Houston, TX, offering local presence and best-quality rigging practices to facility owners and contractors.

Search local rigging providers with verified certifications and documented lift histories. You can also contact JLL Fab directly for on-site consultation about local lift needs.

Load weight, center of gravity, lift radius, and site conditions determine crane type and configuration. Engineering calculations guide the decision.

Yes, crews include certified signalpersons, riggers, and a supervising professional rigger for complex lifts.

We supply rated slings, shackles, spreader bars, and hoisting equipment as needed, as well as arranging for rent cranes and ancillaries to the appropriate schedule to the project.

Yes, we have a documentation package that consists of lift plans, risk assessment, and permitting support where necessary.

The lead time is a factor of complexity. After reviewing site-related information, we deliver a schedule and resource plan to achieve the target move window.