-

By Admin

-

February 8, 2024

- 3 Comment

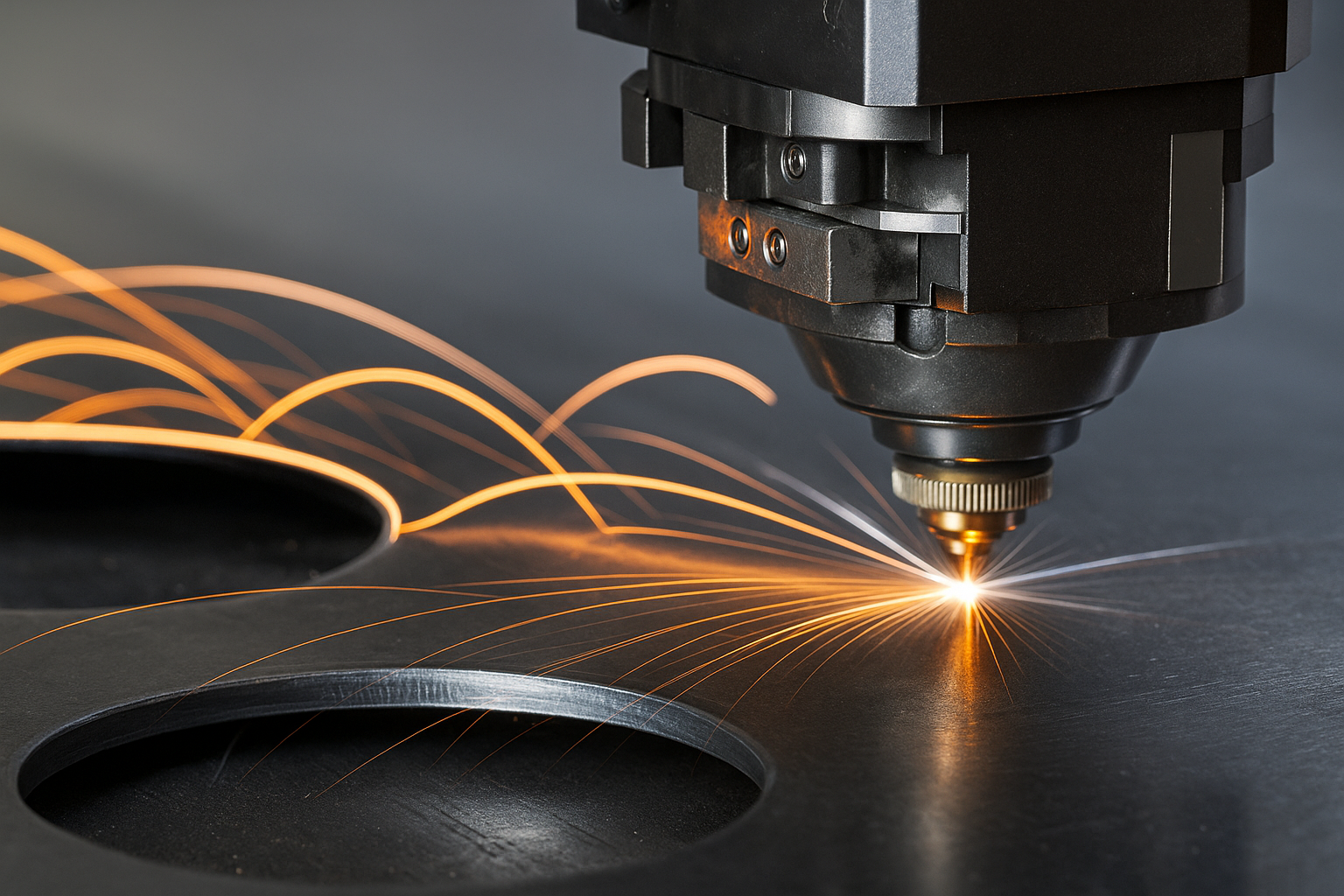

CNC Laser Cutting in Fabrication: What Every Business Should Know

CNC laser cutting is a modern and accurate way to cut sheet metal using a powerful laser controlled by a computer. It helps create smooth edges, detailed shapes, and parts that fit perfectly into real equipment and products. Many businesses choose CNC laser cutting because it supports both simple and complex designs without needing extra tools or a long setup time. It also reduces material waste and helps projects finish faster. From custom brackets to machine components, this process is useful for many industries, including HVAC, construction, and manufacturing. In this guide, you will learn what CNC laser cutting is, how it works, and why choosing the right fabrication partner can improve quality and reliability for your business projects.

What is CNC Laser Cutting

CNC laser cutting is a sheet-metal process in which a laser beam follows precise computer numerical control instructions to cut metal into the required shape. The CNC system guides the laser with high accuracy, so every cut matches the design perfectly. This method works well for straight lines, smooth curves, holes, and detailed patterns. It also keeps the edges clean, which means less finishing work is needed later. Businesses use CNC laser cutting when they want consistent results for many parts at once. It is reliable for different metals and thicknesses, making it a popular choice for custom projects and production work. Overall, it provides better precision and faster results compared to traditional cutting tools.

Benefits of CNC Laser Cutting for Businesses

Through CNC laser cutting, businesses get accurate metal parts faster, with clean edges and reliable repeat results that support better performance and smooth installation in real projects.

Key Benefits

- High precision that keeps every part consistent with the original design

- Smooth edges that reduce or remove the need for finishing work

- Ability to cut detailed shapes and fine patterns easily

- Fast production that helps projects stay on schedule

- Efficient material usage that reduces waste

- Suitable for large orders and repeat production with consistent results

- Works with different metals and thicknesses for more project options

Materials Used in the Process

Different metals are selected based on how strong the part must be, where it will be used, and how long it should last.

Common Materials

- Stainless Steel

Provides strong durability and corrosion resistance, making it ideal for industrial projects and outdoor environments requiring long-lasting, reliable performance every day. - Mild Steel

Offers great strength at lower cost, making it suitable for many general fabrication needs across various industries and commercial applications. - Aluminum

Lightweight and easy to handle, commonly used when reduced weight, simple installation, and smooth finishing are important for business operations. - Galvanized Steel

Features a protective zinc coating that prevents rust, making it useful for outdoor parts facing moisture and weather exposure regularly. - Copper and Brass

Known for good conductivity and decorative appearance, ideal for electrical components or metal designs requiring polished, attractive finishes that stand out.

How the Process Works

The cutting workflow follows a clear sequence, so each part is produced with the correct shape, accuracy, and finish for real project needs.

Simple Step-by-Step

- Design Creation

A digital file is prepared with correct shapes and measurements, ensuring every detail matches what the business requires for proper functionality. - Programming

The design is uploaded into the CNC system, guiding the laser path with complete accuracy for consistent results across multiple parts. - Material Positioning

The metal sheet is secured on the cutting table to avoid movement and maintain perfect alignment throughout the entire cutting operation. - Cutting Operation

A focused laser beam follows programmed lines, producing clean edges and accurate shapes that fit exactly where they are needed. - Final Inspection

Each part is checked carefully to confirm all cuts meet the original design and support smooth installation or assembly later.

Applications Across Different Industries

Many businesses rely on this cutting method because it supports detailed shapes, fast production, and strong performance in a wide range of jobs.

Where It Is Commonly Used

- HVAC Systems

Used to create vents, panels, and fittings that improve airflow performance while maintaining accurate sizing for smooth and secure installation. - Construction Projects

Supports brackets, framing parts, and architectural details that add strength, durability, and visual appeal to commercial spaces and large buildings. - Manufacturing

Produces machine parts that require exact measurements, helping equipment work properly and increasing reliability in busy industrial environments every day. - Automotive Work

Helps form lightweight and precise metal components that fit perfectly, supporting safety and performance across various types of vehicles. - Electrical and Electronics

Creates enclosures and mounting plates that keep wiring secure, protected, and organized in different business settings and technical installations.

Why Choose a Local CNC Laser Cutting Partner?

Working with a nearby expert makes the entire process easier to manage while helping businesses finish projects faster with better communication.

Key Advantages

- Faster Turnaround

Local support avoids long shipping delays, allowing urgent jobs to be completed quickly and keeping important business schedules running smoothly. - Easy Communication

In-person meetings and fast responses make it simple to review designs, approve changes, and solve issues without wasted time. - Better Quality Control

Close collaboration ensures every part meets requirements, with easy inspection and adjustments before final delivery to the worksite. - Convenient Deliveries or Pickups

Shorter travel distance helps parts arrive quickly and in perfect condition, ready for immediate use in ongoing projects. - Stronger Business Relationships

Local partnerships support long-term teamwork, leading to smoother future projects and trusted support whenever new needs appear.

Why You Should Trust JLL Fab

Partnering with the right fabrication company can make a big difference in the quality and success of your project. JLL Fab brings a skilled and experienced team that understands what businesses need from precision-cut metal parts. All services are handled in-house, from design to finishing, which helps maintain consistent quality and faster delivery. Communication is always clear and open, so you can easily approve designs, request updates, and stay informed throughout production. Every part is inspected carefully to match exact specifications and work properly in the final application. With a strong local presence, we offer faster support, reliable deliveries, and a trustworthy long-term partnership for future fabrication needs.

Laser cutting has become one of the most reliable ways to cut metal parts with accuracy and smooth edges that look professional and fit correctly. When the cuts are right the first time, businesses save time during installation and get a stronger finish on every project. Working with a local provider also makes planning easier, because communication is faster and deliveries stay on schedule. JLL Fab is ready to support your next project with quality laser cutting and friendly service you can count on. If you need custom parts or want help bringing your design to life, contact our team today and let us help you move forward with the right solution.

Accusamus iusto odio dignissimos ducimus blanditiis praesentium voluptatum deleniti atque corrupti quos dolores

Deleniti atque corrupti blanditiis iusto odio dignissimos ducimus blanditiis praesentium voluptatum deleniti atque corrupti quos dolores

Ducimus blanditiis iusto odio dignissimos ducimus blanditiis praesentium voluptatum deleniti atque corrupti quos dolores